While wearing gloves in a cleanroom is standard practice those who wear gloves are less likely to wash or clean their hands prior to donning gloves.

Clean room clothing standards.

A cleanroom or clean room is a facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items integrated circuits crt lcd oled and microled displays.

Polyethylene ideal for short term barrier to most fluids.

Clothing and apparel for cleanrooms and labs cleanroom apparel must provide a barrier from micron sized particles but different classes of cleanroom or aseptic environments have different garment requirements.

Cleanroom protective clothing standards osha.

Cleanroom clothing materials selection guide less protection less clean.

But what cleanroom clothing is useful for the individual cleanroom classes in terms of particle emission product and customer protection.

In the uk british standard 5295 is used to classify cleanrooms.

Poor moisture vapor transmission.

It outlines 10 classes of cleanroom along with the type of.

Class 10 000 cleanrooms require workers to wear fewer protective garments than cleanrooms with a lower classification but still require the use of cleanroom clothing such as face masks hair and beard covers and lab coats or other frocks to cover street clothing.

While osha does have guidelines for industrial cleaning that includes information on cleaning cleanrooms it does not have a standard for cleanroom protective clothing.

Since polyethylene can be ripped easily it is ideal for extremely light duty applications.

Hand washing best practices for cleanrooms.

Clothing standards charts for non aseptic and aseptic cleanroom applications provided by uniclean.

Watches jewelry and any clothing should be stored on the dirty side of the gowning room.

Cleanrooms are designed to maintain extremely low levels of particulates such as dust airborne organisms or vaporized particles.

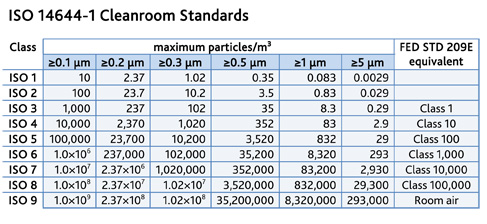

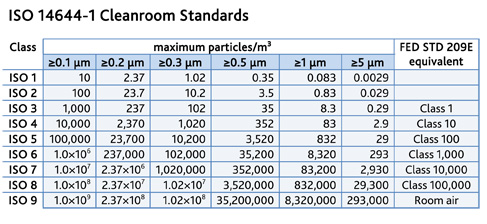

The current international standard for cleanrooms is iso 14664.

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

Don t smoke 30 minutes before entering.

Is it about compliance with the cleanroom class and product protection the table of the american institute of enviromental sciences and technology iest below gives an indication.